Hi All

For most of the warehouses, the generic requirement is to reflect the stock in newly configured warehouse in the system. So that it matches with the reality. In EWM, we have two ways for this.

1. Create Initial stock in MIGO of ECC (movement type 561). This creates inbound delivery and distributes to ECC. Once the delivery is in EWM, the normal inbound delivery processing steps are followed.

2. Prepare CSV file with all the products/HUs and their quantities. Upload this CSV file into EWM.

In this, I'll explain the process of uploading the initial stock using CSV file.

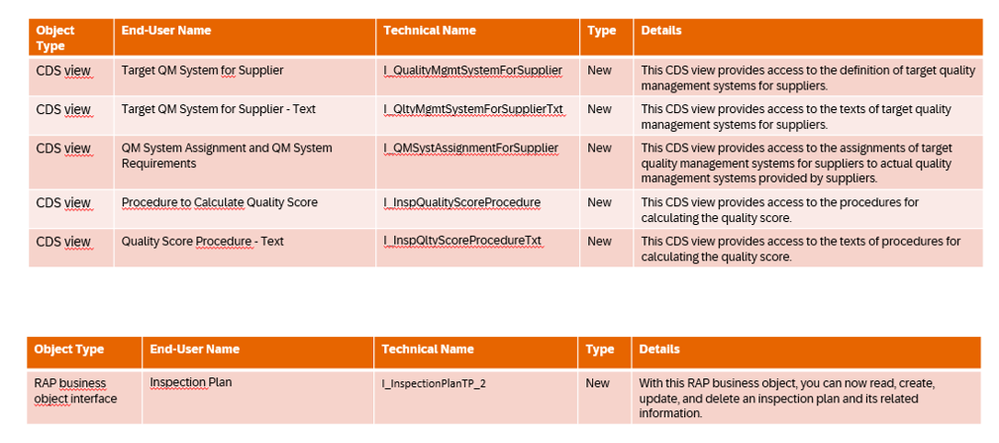

Useful references for preparing the CSV file:

Also you can refer SAP Note: 974852 and download CSV file template.

- Fill the HU & Product details and save file as CSV file.

- Go to TCode: /SCWM/ISU, browse and select CSV file.

- Click on Upload button.

- Check the uploaded data.

- Click on execute button, stock will be uploaded and posted to ERP.

Before:

I have tried to put stock in empty bin “6”. (/n/scwm/mon)

After:

After upload, you'll get a log saying HU is created for material and material document posted. By default "Do Not Post Data in ERP" check box will be unchecked. Because of this, after successful upload, material document posted with 561 movement type.

See below material document posted in ECC after stock upload in EWM.(MB51)

URL given above explains you two variants of stock upload.

1. Without HU

2. With HU (internal or external number range)

Also, good thing about this transaction is (/scwm/isu), after upload you can view the file content in CSV(XLS) format there itself and edit and save the data for upload. Otherwise you can also access the files stored on application server.

Few notes from observations:

1. Packaging specification is not required to defined, to upload stock via CSV file.

2. While uploading more than one HU or Product or both, fields HU, Higherlevel HU(if there are multiple layers in one HU), Highest HU, Line ID must be filled appropriately.

HU - This is unique ID for each HU (a sequence number can be given). For HU, this unique ID should be given and for products inside this should be given. On the same lines, respective HU IDs should be filled for Higherlevel HU and Highest HU.

Line ID is a sequence across rows in CSV.

3. After linking product to HU as above, Storage bin mentioned for Highest level HU will only be considered. If you give different bin for product which even does not exist in the wh, no error will be thrown.

eg:

Item Category,Product,Owner,Partner Role,Batch,Stock Type,Type,Sales Order/Project,Sales Order Item,Usage,Party Entitled to Dispose,Partner Role,Country of Origin,Quantity,Base Unit of Measure,Handling Unit Type,Storage Bin,GR Date,GR Time,Shelf Life Exp. Date,Packaging Material,ExternalNumberAssgmt,Handling Unit,Higher-Level HU,Highest-Level HU,Line ID,Reference to Line,Total Weight,Loading Weight,Weight Unit,Tare Weight,Weight Unit,Total Volume,Loading Volume,Volume Unit,Tare Volume,Volume Unit,Total Capacity,Net Capacity,Tare Capacity Key Fig.,Length,Width,Height,Unit of Dimension,Maximum Weight,Excess Wgt Tolerance,Tare Weight Variable,Maximum Volume,Excess Volume Tol.,Closed,Maximum Capacity,Max. Packing Length,Max. Packing Width,Max. Packing Height,Unit of Measure,Serial Number,Valuation Quantity,Valuation Unit,Valuation Measured,Certificate Number

1,,,,,,,,,,,,,,,E1,BIN3,,0:00:00,,PACKMAT,,1,,1,1,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

4,PRODUCT1,BP1,BP,,F1,,,,,BP1,BP,,1,EA,,6,,0:00:00,,,,1,,1,2,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

1,,,,,,,,,,,,,,,E1,BIN3,,0:00:00,,PACKMAT,,2,,2,3,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

4,PRODUCT1,BP,BP,,F1,,,,,BP1,BP,,1,EA,,6,,0:00:00,,,,2,,2,4,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

1,,,,,,,,,,,,,,,E1,BIN3,,0:00:00,,PACKMAT,,3,,3,5,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

4,PRODUCT1,BP,BP,,F1,,,,,BP1,BP,,1,EA,,6,,0:00:00,,,,3,,3,6,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

1,,,,,,,,,,,,,,,E1,BIN3,,0:00:00,,PACKMAT,,4,,4,7,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

4,PRODUCT1,BP,BP,,F1,,,,,BP1,BP,,1,EA,,6,,0:00:00,,,,4,,4,8,0,,,,,,,,,,,0,0,0,,,,,,0,,,0,,0,,,,,,,,,

Thanks

Sasidhar Gupta