This blog explains SAP EWM and QM integration using DMR, SKIP lot and Workflow. This blog doesn’t cover basic setup between EWM and QM integration. If you need to know basic setup for EWM and QM integration, please go through EWM_ERP_QM_Basic_Inspection_Process

Background: As part of the inbound processing of quality managed products, working with trusted suppliers can create significant efficiencies. As supplier is trusted and has an established track record to deliver stock with less defects, businesses can avoid additional inspection activities for its users by inspecting stock for the first time it delivered and then only after certain lots are received.

This functionality can be achieved using SKIP lot function in quality management. In the context of SKIP lots, it doesn’t mean that inspection lots are not created. Instead, Inspection lots are created and auto usage decision is provided for inspection documents. To make this functionality work in real time, workflow event setup is used and explained in this blog.

Following aspects are covered:

1. GR posting with quality inspection scenario execution

2. Essential configuration settings

3. Master data

4. Technical aspects for SKIP lot functionality

5. Troubleshooting

GR posting with quality inspection scenario execution:

There are two variants explained with scenario execution in the system.

· GR posting with quality inspection and Manual usage decision

· GR posting with quality inspection and Auto usage decision using SKIP lot functionality

Scenario 1: GR posting with quality inspection and Manual usage decision

Assumptions: For purchase of new product, inspection execution is essential.

Plant/Storage Loc./Warehouse – CP01

Product – PROD-CP-QI-DPR-02

Create Purchase order in ERP

Create inbound delivery in ERP

Inbound delivery created and distributed to EWM

EWM:

Inbound delivery

Execute packaging

Post goods receipt in EWM

ERP side, Goods receipt posted with movement type 101 and stock moved to quality inspection stock

MMBE, Stock can be viewed for quality inspection stock

Inspection lot document created

Enter inspection results and accept

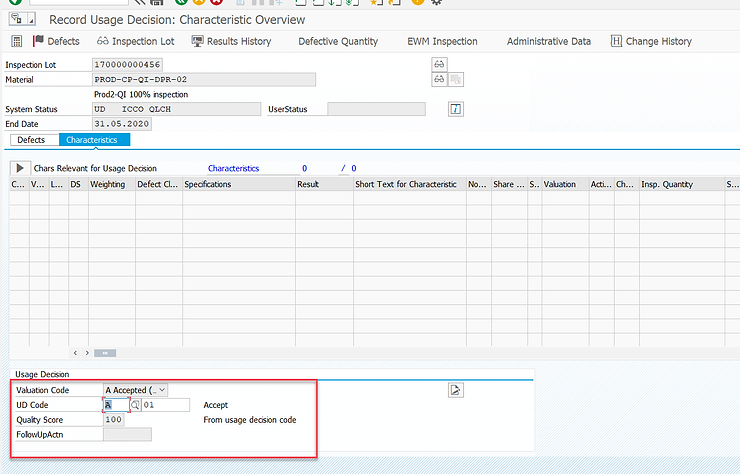

Set usage decision

Inspection lot approval triggers an update to EWM system.

Decision code updated in EWM system.

Additionally, Posting change warehouse document gets created in EWM system. This moves stock from Q2 stock type to F2 stock type. (In case of different stock types ROD(F1) - AFS(F2) setup, stock gets moved to F1 stock type after inspection approval)

Posting change document sends update to ERP system.

Movement type 321 gets posted in ERP system for transfer posting.

Note: Material slip number is updated with EWM warehouse material document number

In MMBE, stock is moved from quality inspection stock to unrestricted stock.

Scenario 2: GR posting with quality inspection and Auto usage decision using SKIP lot functionality

Inbound delivery created and distributed to EWM

EWM side:

Execute packaging

Post Goods receipt

Goods receipt posted successfully in EWM system.

Check inspection document, Inspection document created and auto approved via Workflow user ‘SAP_WFRT’.

Check in ERP system, for inspection document

Choose Text button,

Usage decision was made by Workflow user (SAP_WFRT). Required settings are shown in ‘Technical aspects’ section.

Other postings are same as first variant like:

In the inbound delivery, Goods receipt was posted using 101 movement type and stock was moved to quality inspection stock. Afterwards, based on skip lot, inspection was approved and updated in EWM system. Posting change document gets created in EWM system and stock gets moved from Q2 stock type to F2 stock type. In ERP system, Posting change update triggered and stock moved to unrestricted stock using movement type 321.

Essential configuration settings:

ERP

Following configuration required to set delay time for automatic usage decision

Master data:

ERP system

Material master:

Dynamic modification rule (DMR): QDR3

DMR setup is done with two stages:

Stage ‘1’ for initial stage

Next stage ‘10’ for Skip lot

In this example, after initial inspection next 3 inspections will be auto approved based on SKIP functionality. Afterwards, system will again choose inspection stage 1 where manual inspection required.

Inspection plan: QP03

In the inspection plan, DMR rule can be assigned

Quality level: QDR3

After first inspection, quality level data gets changed with next Stage as 10(Skip lot)

EWM System

Product Master

Inspection rule setup /SCWM/QRSETUP

Technical aspects for auto usage decision:

Prerequisite: Workflow setup configured in SWU3

Event linkage: SWE2

To take usage decision, Setup event linkage for business object BUS2045 and event SKIPPED

At first check function module QAVE_EVENT_CHECK_UD_SKIP gets triggered.

In the check function module, customizing setup for SKIP lot is checked at plant and inspection type level.

Once check function module is successful, event linkage becomes activated and

class 'CL_QM_EVENT_EXECUTE_VE' method 'ON_EVENT' gets processed

Eventually, Function Module: ‘QAVE_PROCESS_AUTO_UD’ gets called and automatic usage decision is made for Skip lots.

Note: Since event receiver is a method call, no workflow template/workflow task setup required. As a result, no work items are created during execution of automatic usage decision.

Troubleshooting:

When SKIP lot auto decision is made using event linkage, following are known issues:

- Event not triggered:

To check SKIPPED event triggered or not, activate event trace transaction using SWELS

Afterwards, check triggered events in SWEL transaction

Even after activation of event trace, if the event is not displayed in SWEL transaction,

it means check function module 'QAVE_EVENT_CHECK_UD_SKIP' is not successfully processed .

- Check configuration settings/master data correctly maintained .

- Additionally, you can debug function module 'QAVE_EVENT_CHECK_UD_SKIP' to find out exact cause

- Event SKIPPED gets triggered but usage decision is not made:

Error: ‘Event entered in event queue’ observed in event trace.

Check for workflow RFC destination setup in SWU3 transaction

Once RFC destination is setup correctly, Auto usage decision gets successfully processed.

- For workflow RFC destination setup, workflow user SAP_WFRT setup is necessary.

Additionally, roles SAP_BC_BMT_WFM_SERV_USER_PLV01 and SAP_S_RFCACL are required for workflow user.

Once workflow related settings are added, successful event trace looks as below:

Additional inputs:

If it is not necessary to take real time automatic usage decision, transaction QA10 can be used to setup batch job for auto usage decision.

SAP QM Training in GURGAON

ResponderExcluir