Our comprehensive guide on the kitting process in SAP EWM! You’ll find all the information you need to optimize your operations and streamline your workflow. By implementing this efficient system, you’ll be able to enhance productivity and make your business more successful than ever before. Don’t miss out on this valuable resource!

The kitting process within SAP EWM (Extended Warehouse Management) entails the combination or assembly of components or parts to generate a final product.

- Initiation: The kitting process initiates upon the system’s receipt of a request for a particular product or kit assembly.

- Availability Check: The system verifies the presence of all required components or parts within the warehouse inventory.

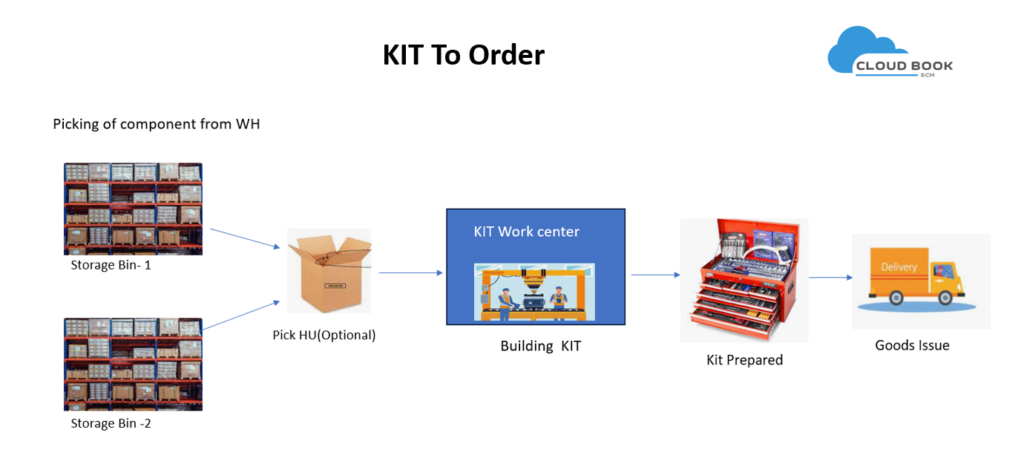

- Picking: The system generates picking tasks to retrieve the reserved components from their respective storage locations within the warehouse.

- Kit Assembly: The picked components are transported to the assembly area or workstation, where they are combined or assembled to create the final kit or product.

- Shipping: The assembled and packed kit is prepared for shipping. Shipping documents, such as packing lists and delivery notes, are generated, and the kit is transferred to the outbound staging area for further transportation.

When we get the demand/order for the kit, then we start preparing/producing the kit. we do not prepare kits to store in inventory.

Required Master data/configuration for the Kitting (KIT to Order) process:

Material Master

a) KIT Header – Final material moved out of warehouse/plant

b) KIT Item – Component gets consumed to prepare the Final product.

Bill of Material –

Exploded with Header and component information.

Item category in ERP for KITS and its related determination setting: –

- Header product – KITH

- Item component – COMP

Activate BC sets if the Header and components type are not available in the system as default entry BC Sets:/SPE/KIT_TO_ORDER

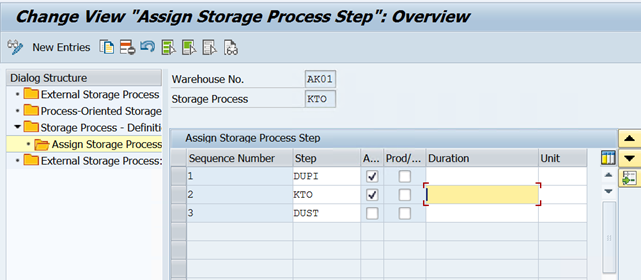

Storage control setting: Having KTO as Kitting WorkCentre.

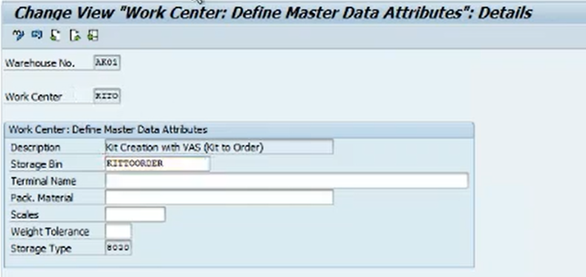

For Kitting the components will be assembled in the KITTING Work center which is assigned to the Kitting WorkCentre layout.

Storage bin assignment for KITTING Work center

Process Flow:

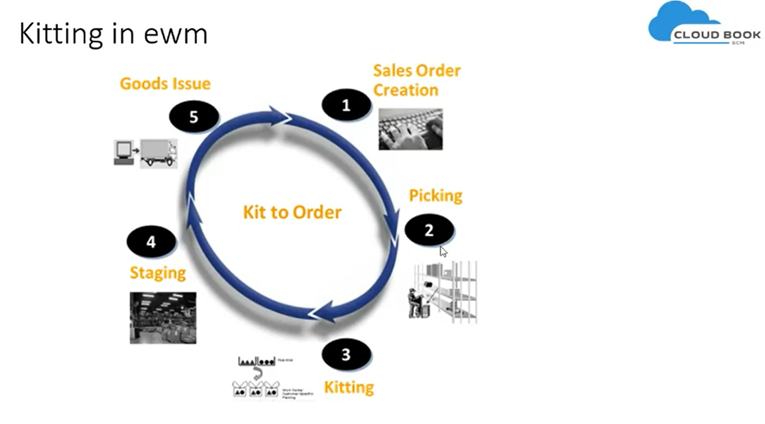

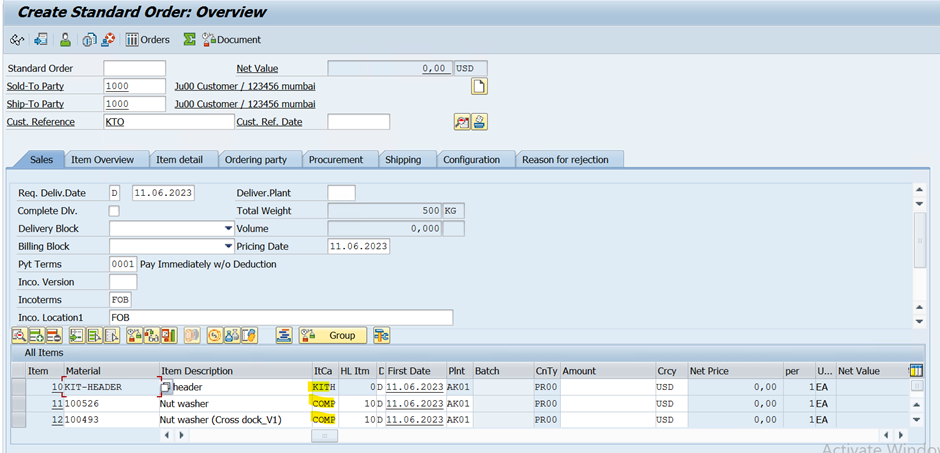

1) Sales order created in SAP ERP /CRM System.

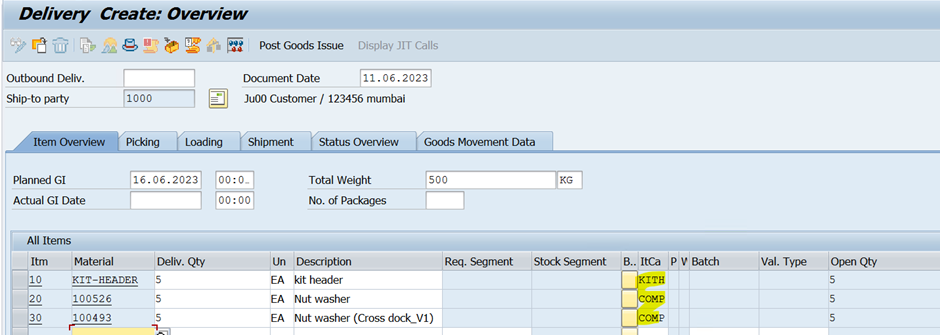

2) Outbound delivery is created in ERP and on saving it gets distributed to EWM.

3) Perform the picking and staging of kit products.

4) Building of KIT In WorkCentre as per Kit order.

5) Moving Final Kit product to Staging Area.

6) Post Goods Issue.

Sales order with KIT Header and Item components (this will get exploded automatically using BOM)

Outbound delivery w.r.t Sales order on saving the delivery gets distributed to EWM

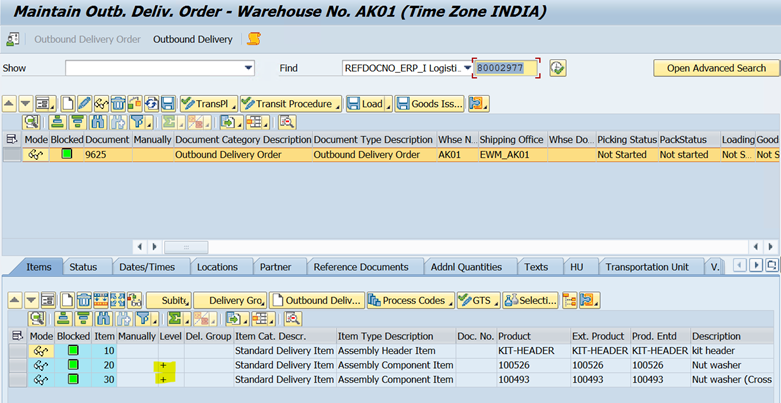

Outbound in EWM

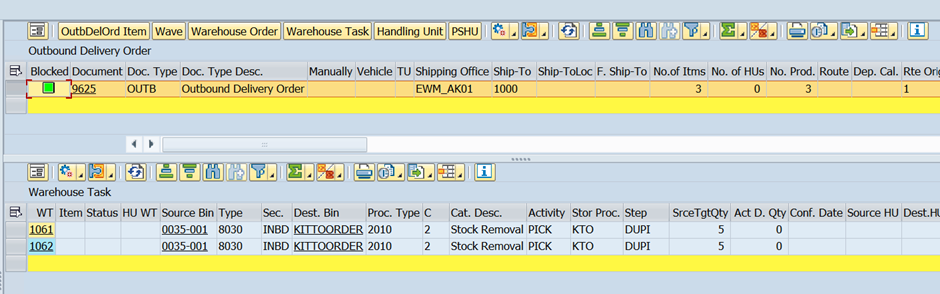

WT created:

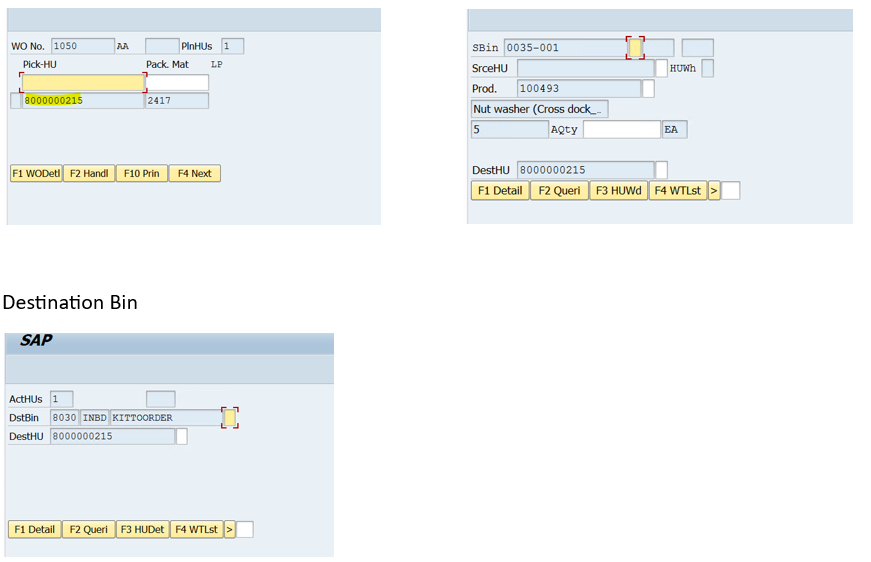

For Kitting the material /component should be packed under the Handling unit hence during WT confirmation to move the component to the KIT Work center the system will create Pick HU.

Pick HU

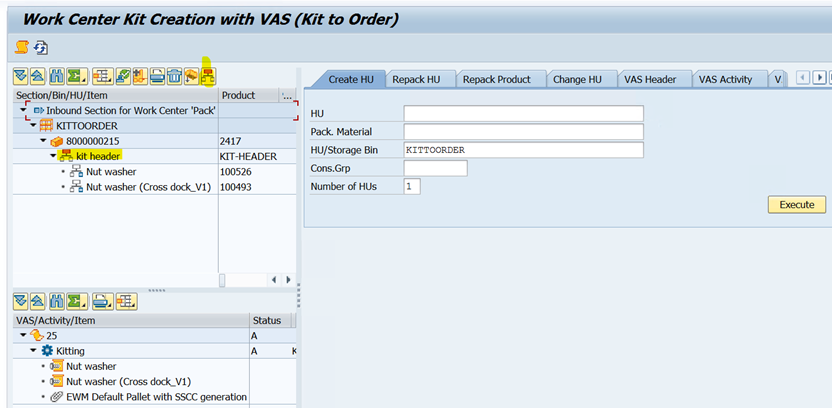

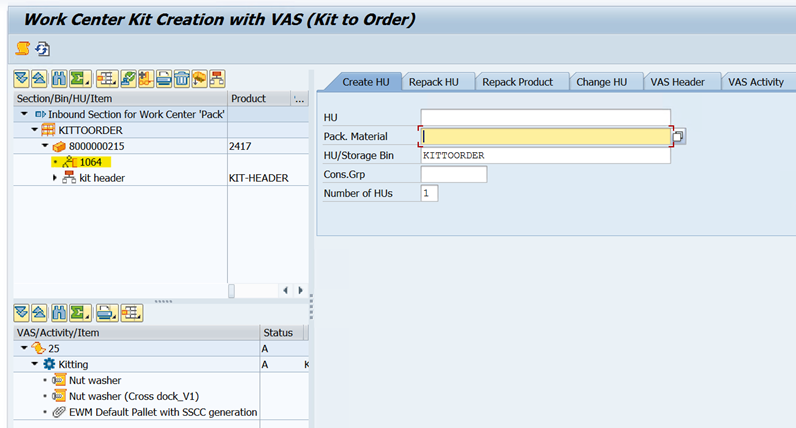

Use WorkCentre to perform the Kitting operation /SCWM/VASEXEC and perform Kitting operation.

Complete HU to move the material from the Work center to the Staining Area and confirm the WT.

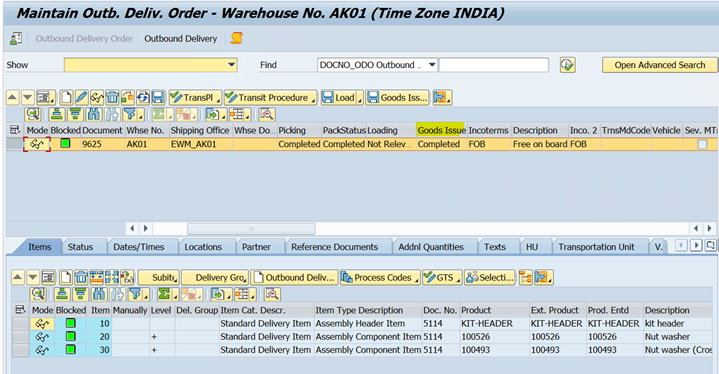

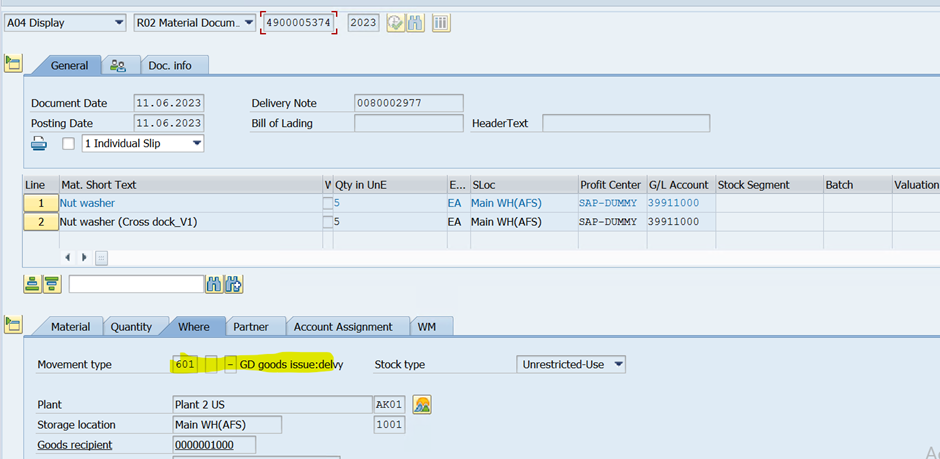

Perform Goods Issue

In ERP – Goods issue of component

End of process ****************************

Get ready for an exciting journey as you immerse yourself in the realm of SAP at SCM-Cloudbook, a reputable SAP training centre located in Pune. We take great pride in being recognized as a top-notch player in the industry. Our exceptional SAP courses will provide you with the knowledge and skills needed to thrive in this field. If you are looking for the best SAP courses in Bangalore, know that we are here to support you.

The Blog by : Amith Kumar (SCM-CLOUDBOOK)

For more blogs: Blog (cloudbook.co.in)

Source: https://cloudbook.co.in/blog/sap-ewm-kit-to-order-process/

Nenhum comentário:

Postar um comentário