Introduction

By integrating SAP Extended Warehouse Management (SAP EWM) with production planning and execution, you gain the ability to oversee the storage, movement, and staging of both components and finished products.

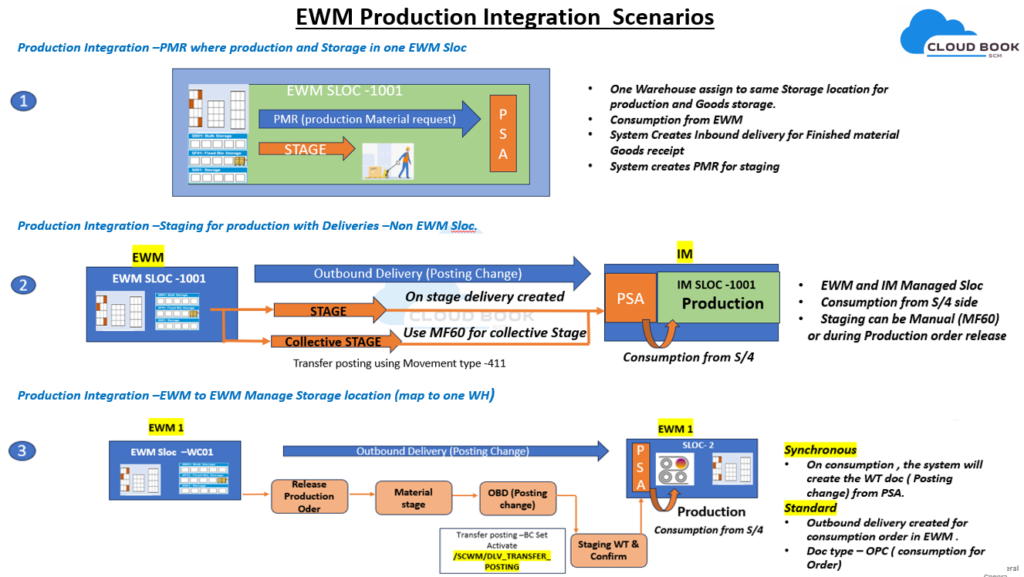

In this blog post, I will delve into the integration of Delivery-Based and Advanced (PMR) Production, illustrating it through various scenarios.

Scenario 1 – Production Integration using PMR (product Material request)

Advanced production integration within S/4HANA Embedded Extended Warehouse Management (EWM) seamlessly incorporates the flow of products to and from production operations. This integration is closely tied to the manufacturing order processing within SAP S/4HANA, enabling efficient material staging, consumption, and the receipt of semi-finished or finished products within the S/4HANA Embedded EWM environment.

The execution of warehouse activities related to SAP S/4HANA Production Orders relies on the utilization of the Production Material Request (PMR) document.

Master data:

- Define PSA in ECC ( PK05) – > PSA1

- Replicate PSA from ECC to EWM – /n/SCWM/PSA_REPLICATE

- Create Production Storage bin – /n/scwm/LS01

- Assign PSA with Production storage bin – Define the storage bin in which you want to stage a particular product or product group within a PSA. /N/SCWM/PSASTAGE

- Material master value related to PSA – MRP View -2

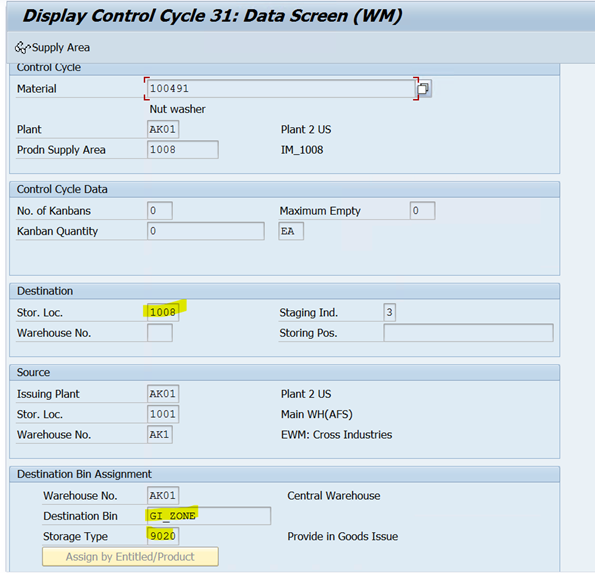

- Define Control cycle –LPK3

- Assign product group to PSA and bin

- Define Work center –CR01

- Create WPT for production Staging (use the type REPL)

- Determine the WPT at time of Staging

Process Step

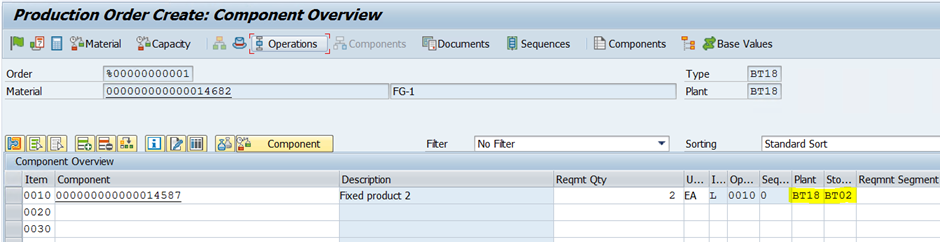

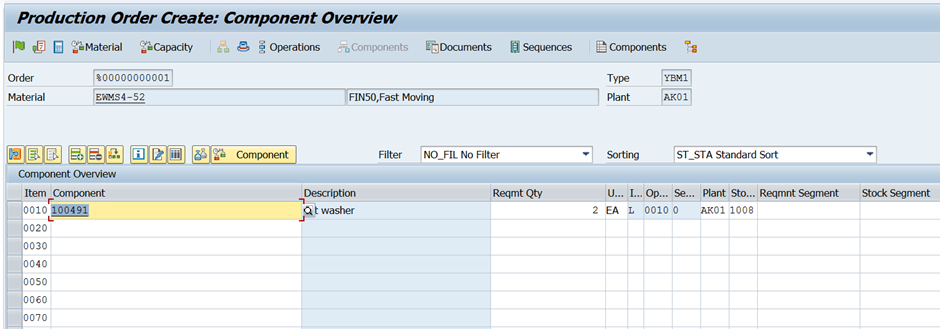

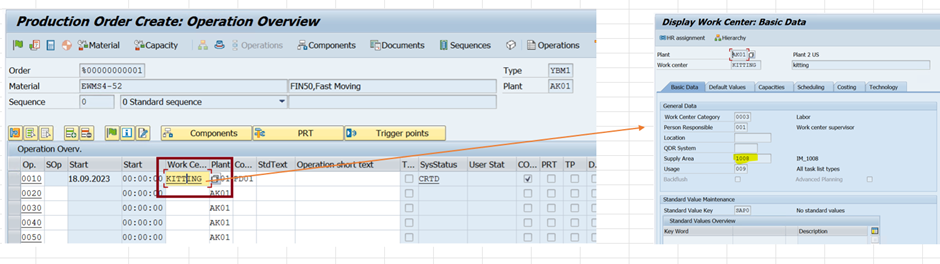

- Create Production order and perform the WM Material staging

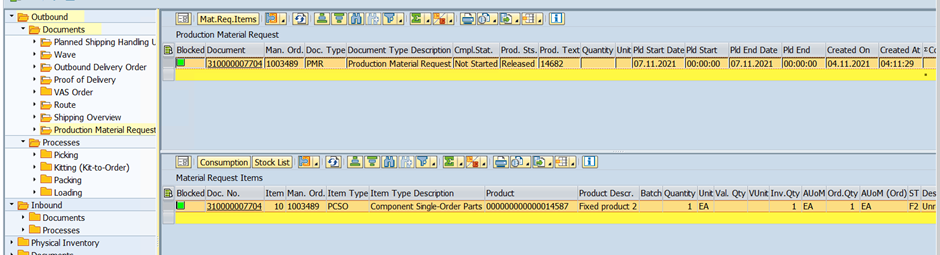

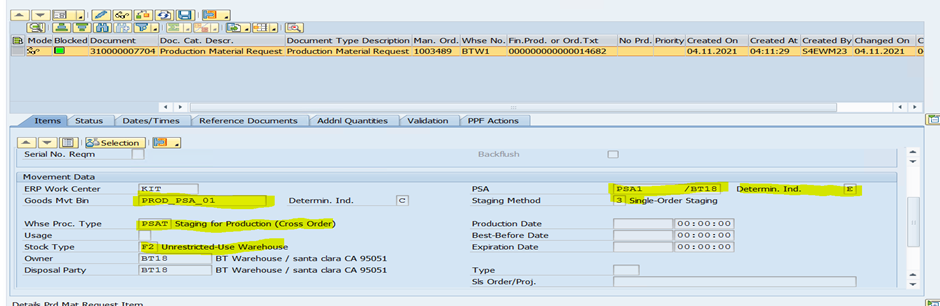

The PMR will be generated once WM simulation executed and PMR can be seen in /n/SCWM/MON

Use Tcode -/N/SCWM/PMR to display the PMR

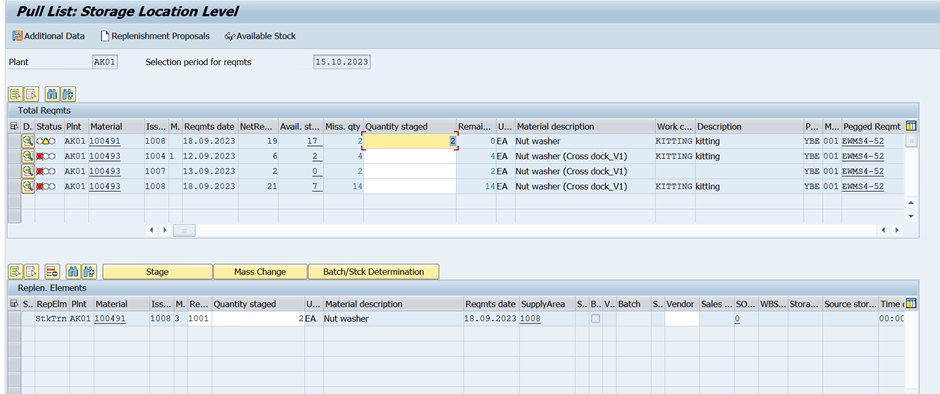

- Create material staging -/n/SCWM/STAGE to move stock from source bin to PSA .

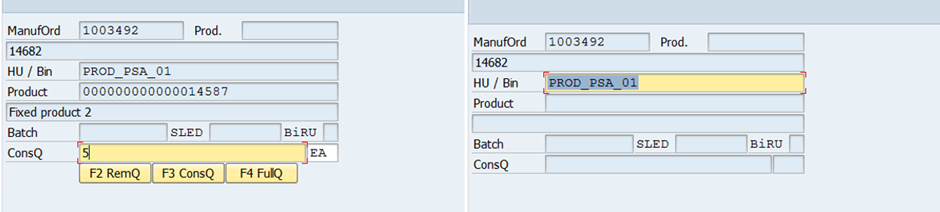

Consumption from PSA

Scenario -2 Delivery-Based Production with EWM involving Two Storage location (EWM & IM managed) with collective Staging using MF60

Process Flow:

Create PSA

- To Create Production order -Production Order

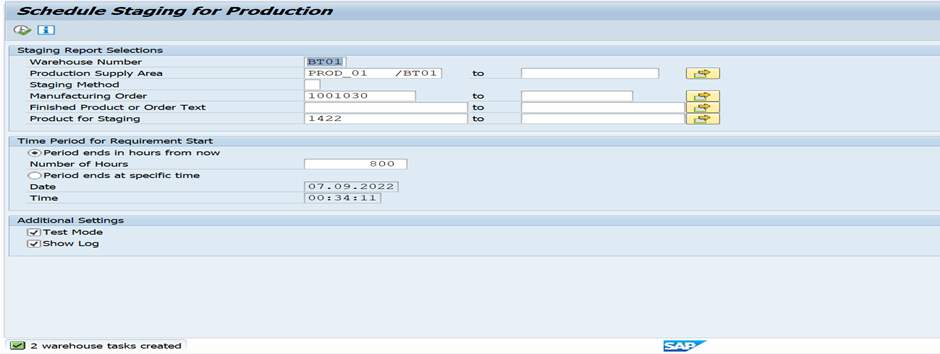

Release the production order and stage the material manual using MF60

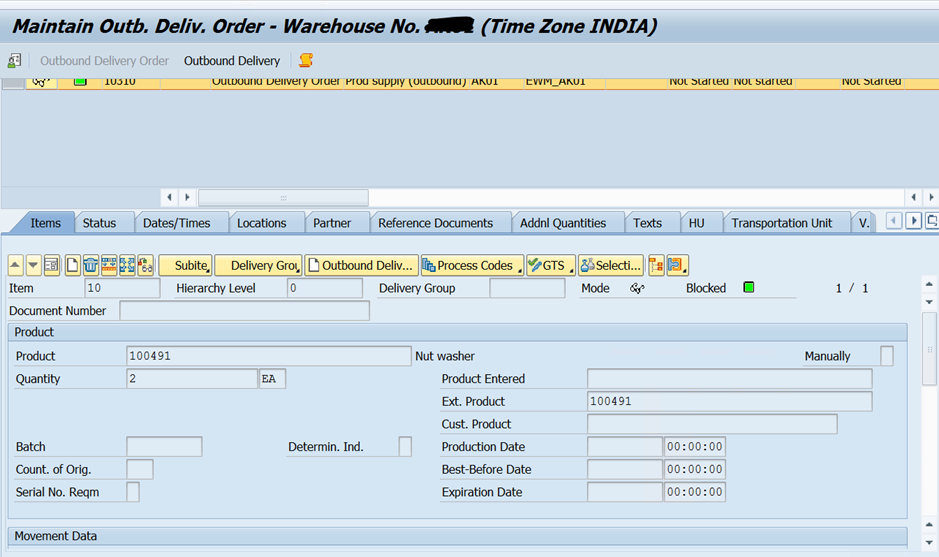

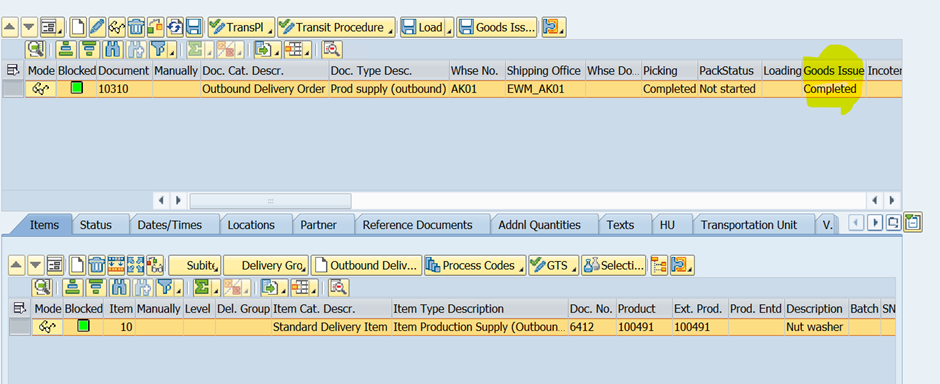

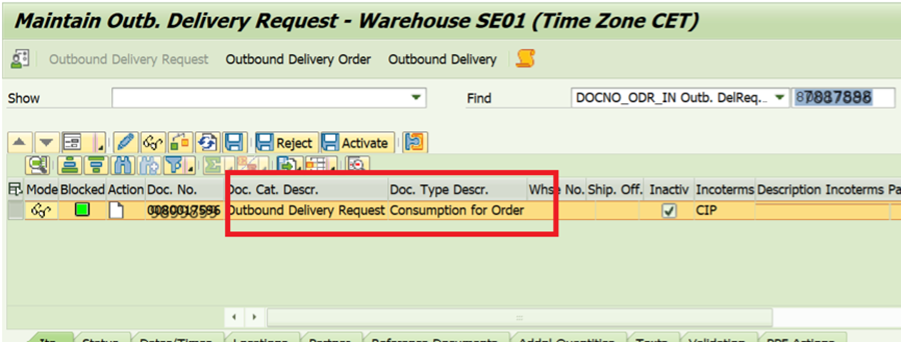

On saving the staging , the system will create an outbound delivery and distribute to EWM system.

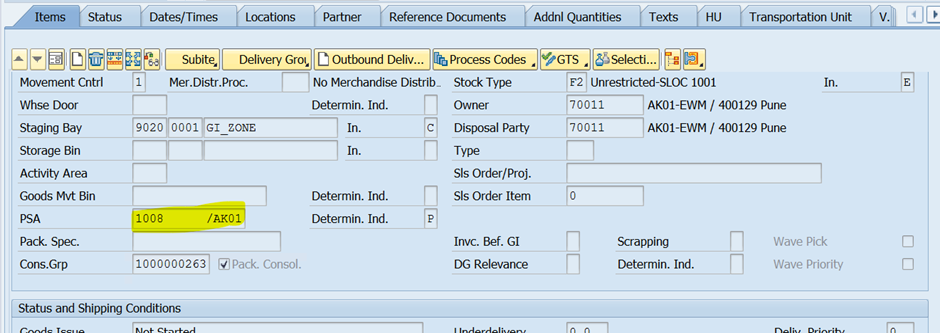

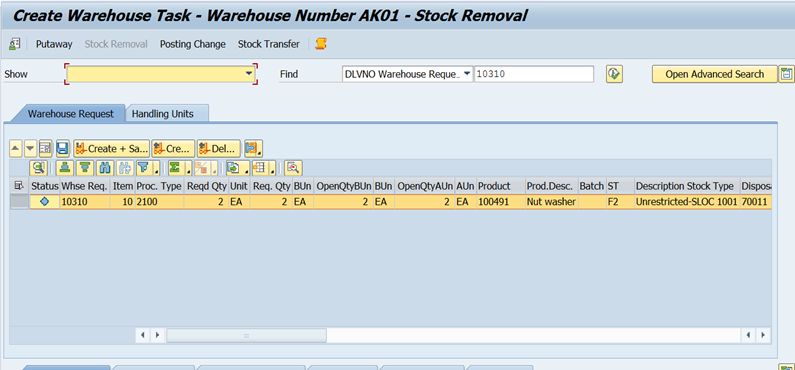

Create Pick task to pick material from EWM and confirm the WT.

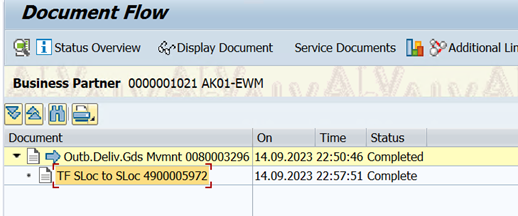

- Preform the Goods issue from EWM

s/4 Outbound delivery

Scenario -3 Delivery-Based Production with EWM involving Two SAP EWM-Administered Storage Locations within a single Warehouse.

In this setup, the system autonomously handles production inventory separately from other stock types. This enhances transparency at the storage-bin level within the SAP EWM system and at the storage location level in the SAP ERP system. During product staging, the SAP EWM system facilitates this process by performing a posting change, which, in the SAP ERP system, translates to a stock transfer between the storage locations.”

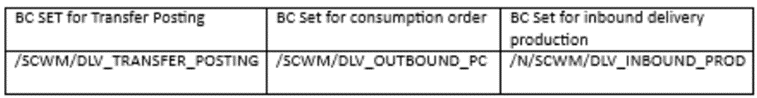

BC sets to be activated:

For Automatic Good issue for Backflush components

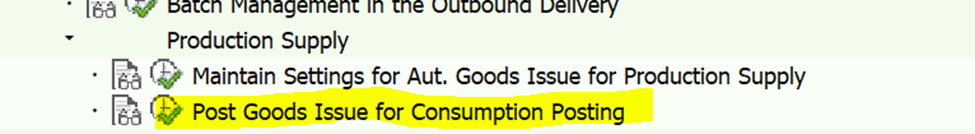

SAP→ EWM→ Goods Issue process→ Outbound delivery → Production supply→ Post goods issue for consumption posting.

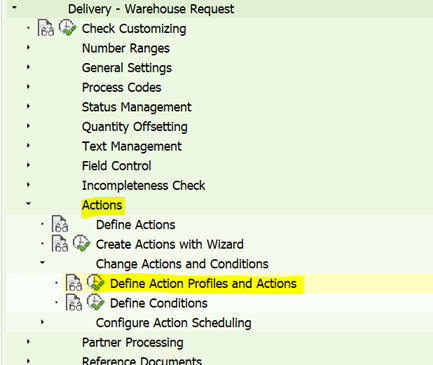

The action profile is assigned to the delivery type must contain action /SCWM/PRD_OUT_POST_GI_PP .

Once the outbound delivery will be distributed to EWM system will be either perform auto goods issue for backflush components or can manually trigger Goods issue from EWM, then the GI posting will be sent to ECC and then GI posting document will be generated.

Process Flow:

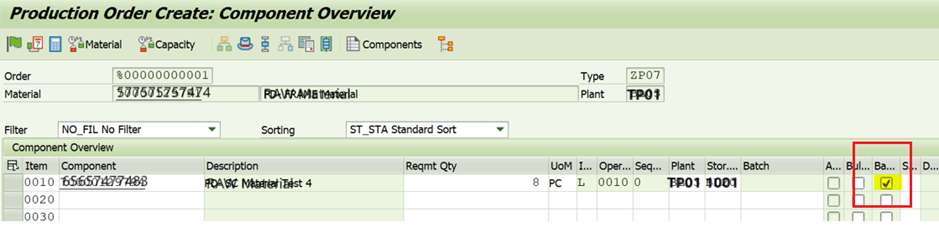

- To Create Production order -Production Order with Backflush Material

- Release the production order and perform WM staging (Manual or Automatic)

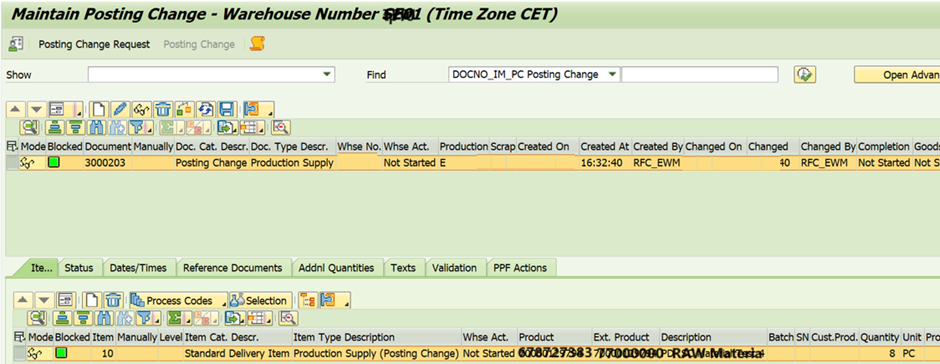

- On release, the system will create the outbound delivery (Posting change) and delivery gets distributed to EWM system for Pick the parts from storage.

- Create Warehouse task → posting change→ Follow on function → warehouse task where the material will move from Production storage type to PSA storage bin

- Create the picking warehouse task

- Confirm the WAREHOUSE TASK.

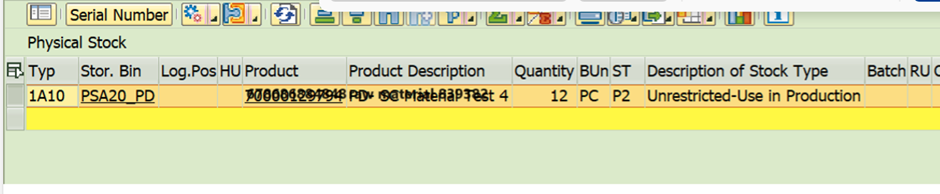

- PSA Storage bin stock available

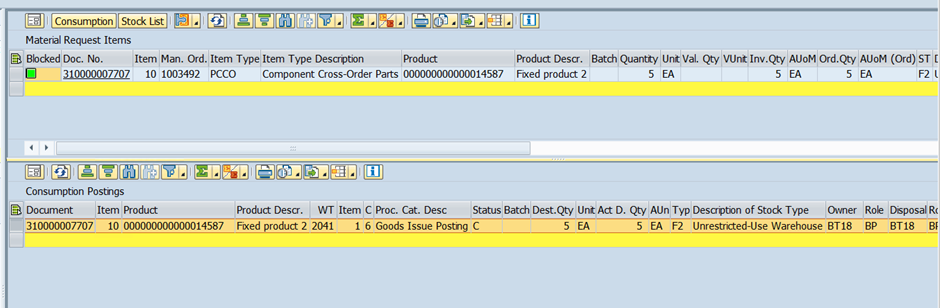

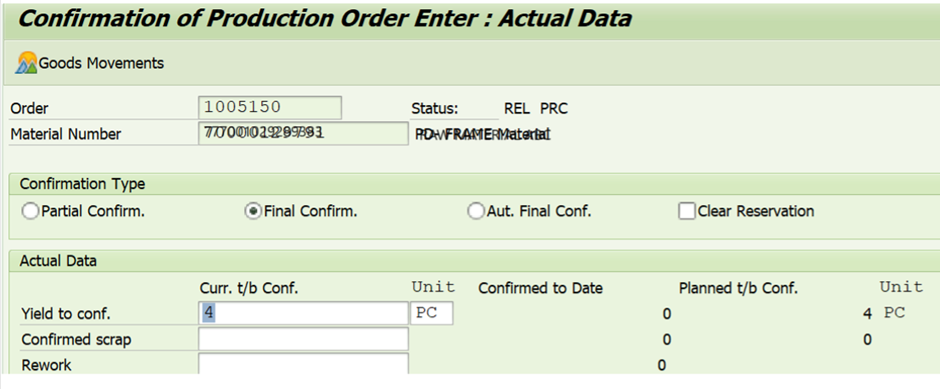

Now, perform the Goods issue of component (MIGO) or production order confirmation ( CO15) any option in ECC and system will create the outbound delivery for components information that needs to be consume and distribute from ECC to EWM.

- The system will generate the outbound delivery to send the component information to EWM as of now in ECC no Goods issue posting o material document will be generated, it will be generated from EWM system.

- Once the outbound delivery will be distributed to EWM system will be either perform auto goods issue for backflush components or can manually trigger Goods issue from EWM, then the GI posting will be sent to ECC and then GI posting document will be generated.

The system will perform the Automatic Goods Issue or Manually triggered the Goods Issue.

This guide provides valuable information on SAP EWM (S/4 HANA) Production Integration scenarios. If you’re interested in expanding your knowledge of SAP, consider exploring sap learning in Pune. Connect with SCM-Cloudbook to embark on an exciting learning journey. Exciting opportunities await!

Blog By

Nitin Kumar

SCM EWM / Logistics Expert / Freelance/ Corporate Trainer / Solution Architect

Nenhum comentário:

Postar um comentário