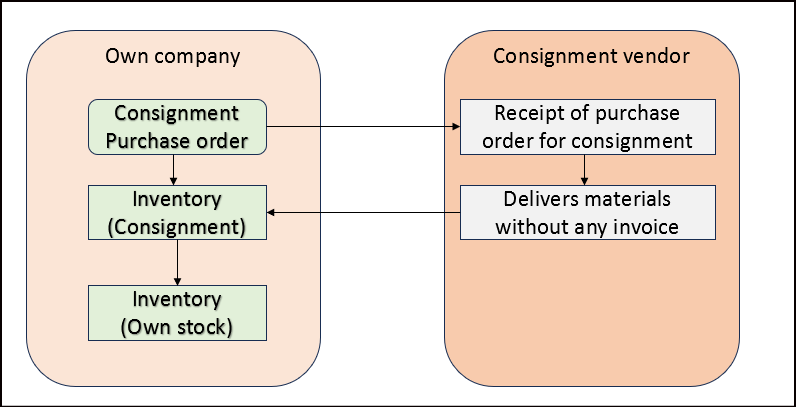

Vendor consignment is a procurement process when the vendor is not needed to be paid immediately on goods receipt of the materials. Vendor still owns the goods after it is delivered from its own premises and received in customer’s premises as consignment stock. Liability to pay (to the vendor) arises only when the goods are withdrawn from the consignment stock and taken into ‘Own stock’. Vendor consignment is used to optimize the inventory and reduce the liability towards the vendor.A typical vendor consignment process is depicted in below image.

Standard SAP ERP supports vendor consignment from very early days of R/3 or ECC . SAP Extended warehouse management (EWM) also supports vendor consignment as illustrated in this blog.

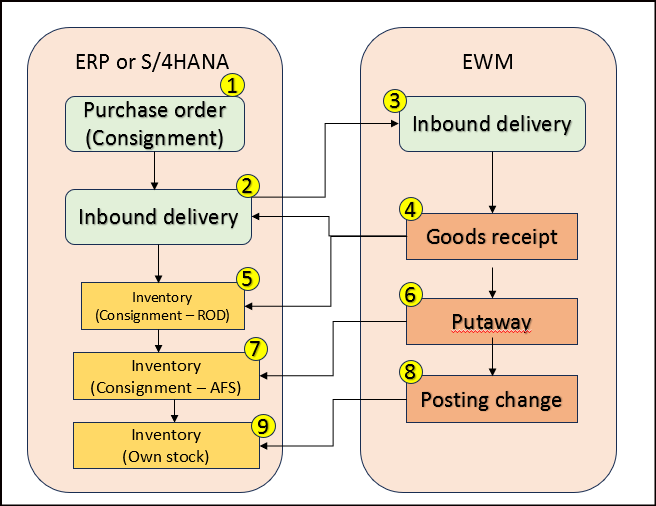

A typical process flow for vendor consignment with SAP ERP or S/4HANA and EWM is depicted in below image and described as below.

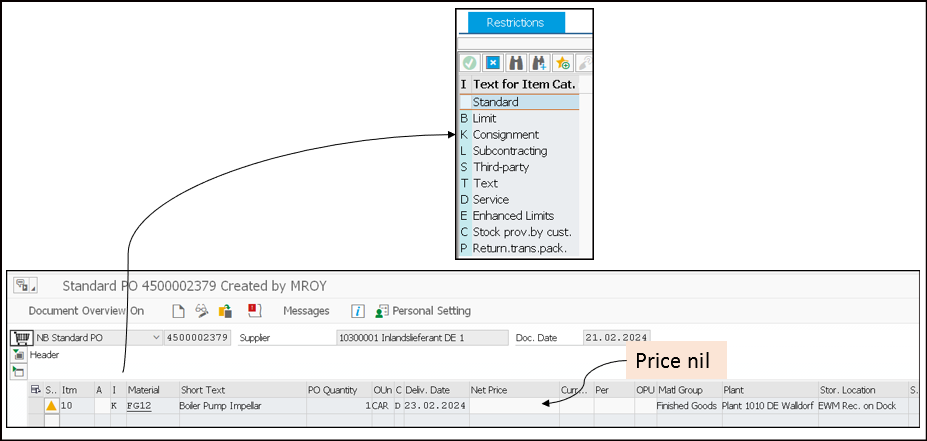

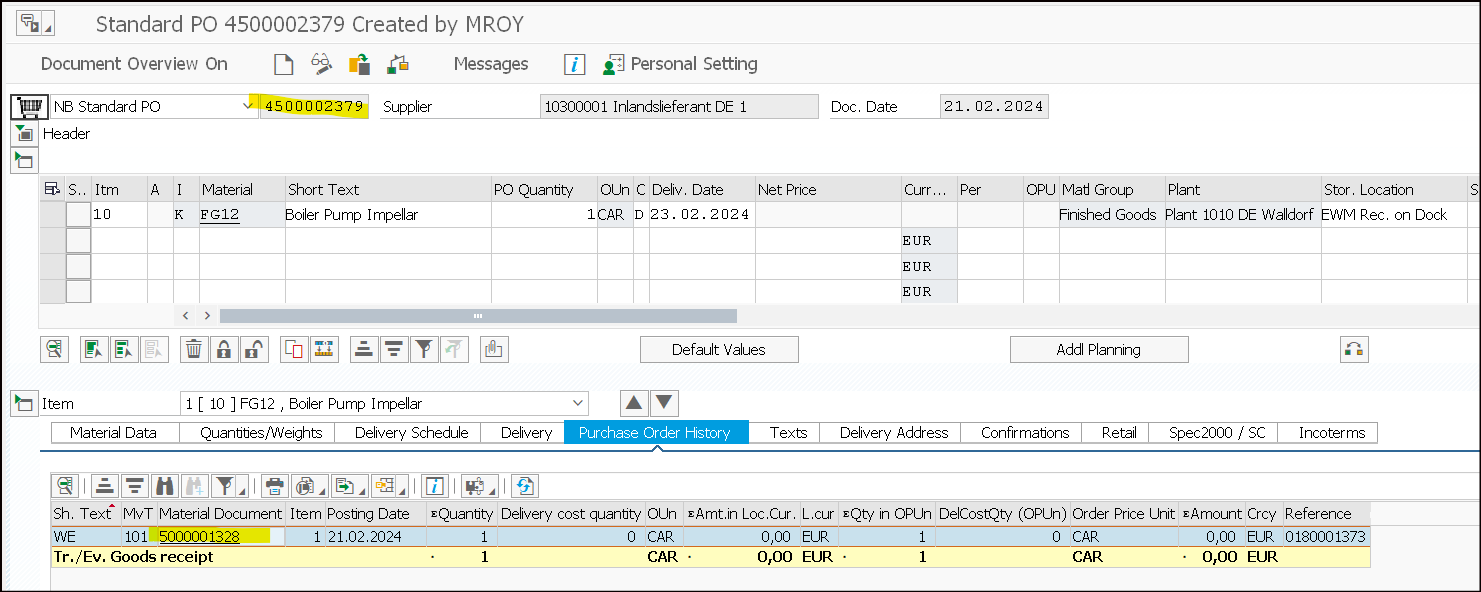

(1) A purchase order with item category K (consignment) is created. Price is nil as the item category is K (consigment).

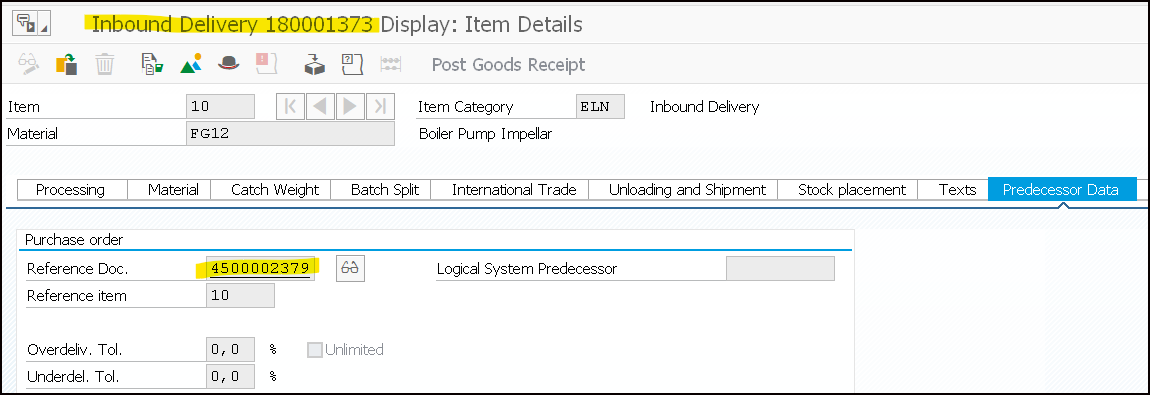

(2) An inbound delivery is created in ERP with reference to that purchase order .

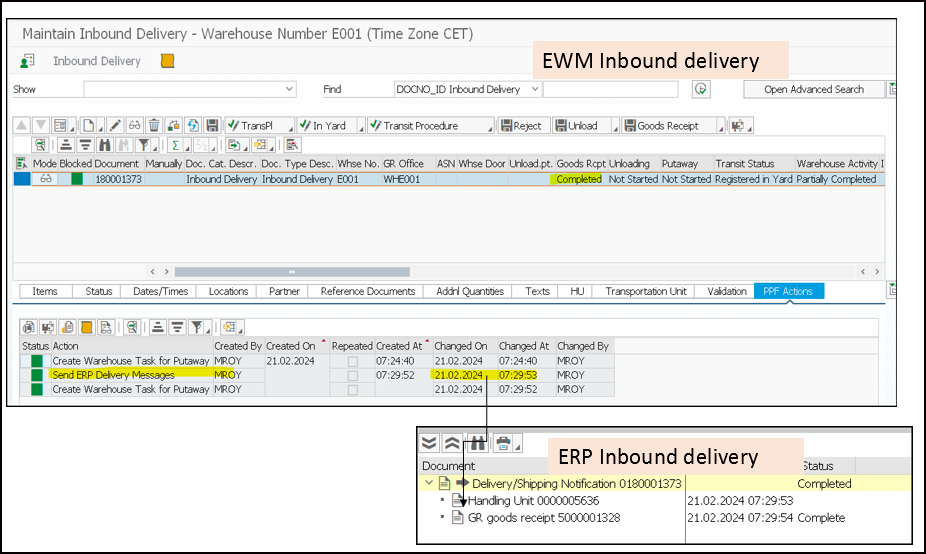

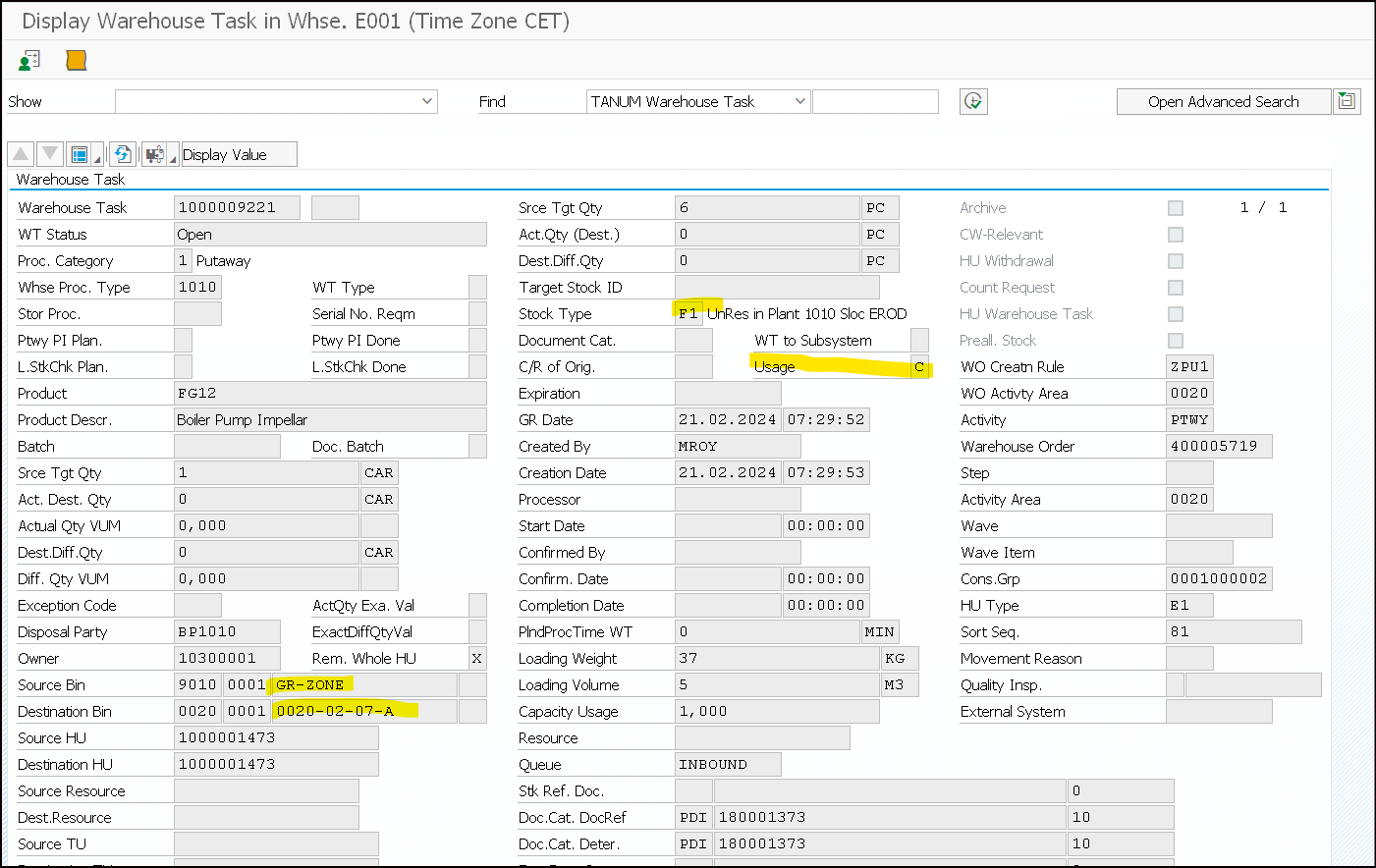

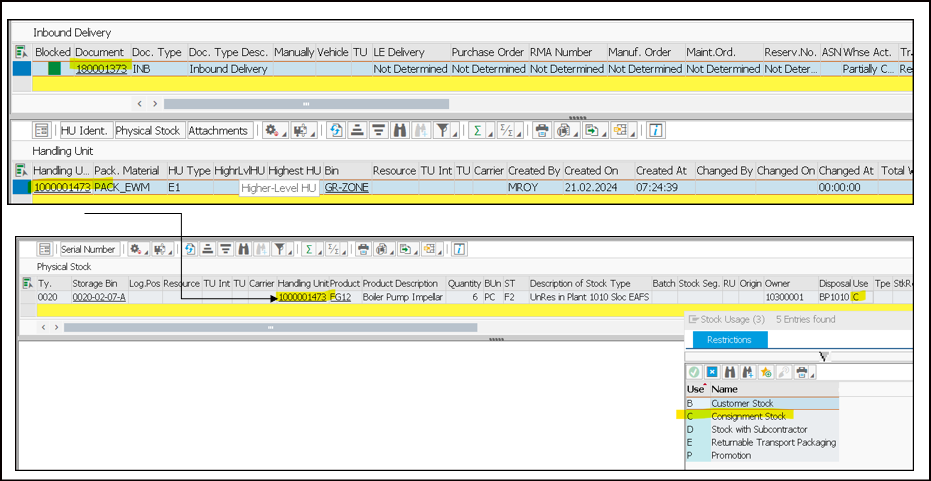

(3) An inbound delivery is created in EWM with item usage as C(Consignment stock) and stock type F1 (Received on dock).

(4) Good receipt is completed in EWM inbound delivery which triggers PPF message towards ERP updating the ERP inbound delivery .

And a warehouse task is created for movement of goods from the goods receipt zone to the destination bin.

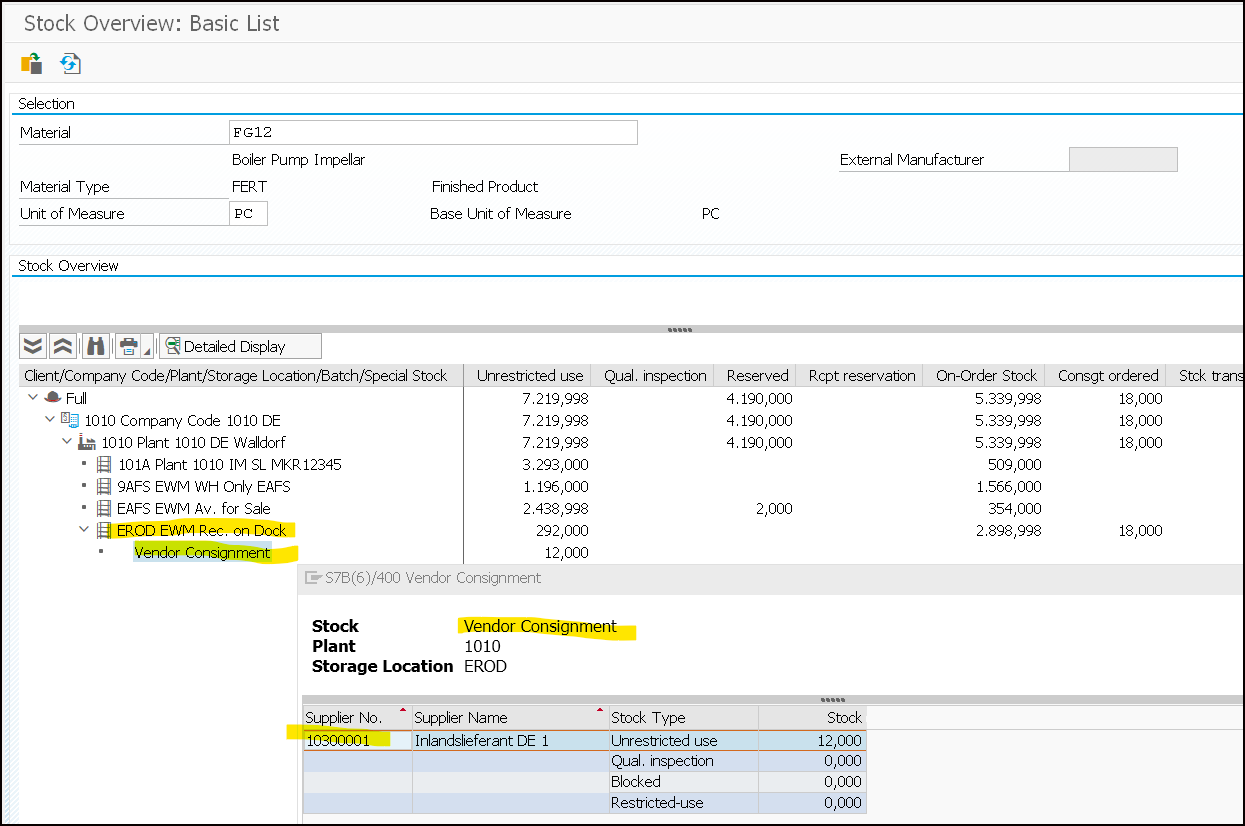

(5) ERP stock gets updated as vendor consignment corresponding to the vendor with storage location ROD (Received on dock).

A material document is created in ERP with movement type 101 as displayed in purchase order history of the purchase order.

The material document has no accounting document (and hence no liability to pay to the vendor on goods receipt of stock as vendor consignment) .

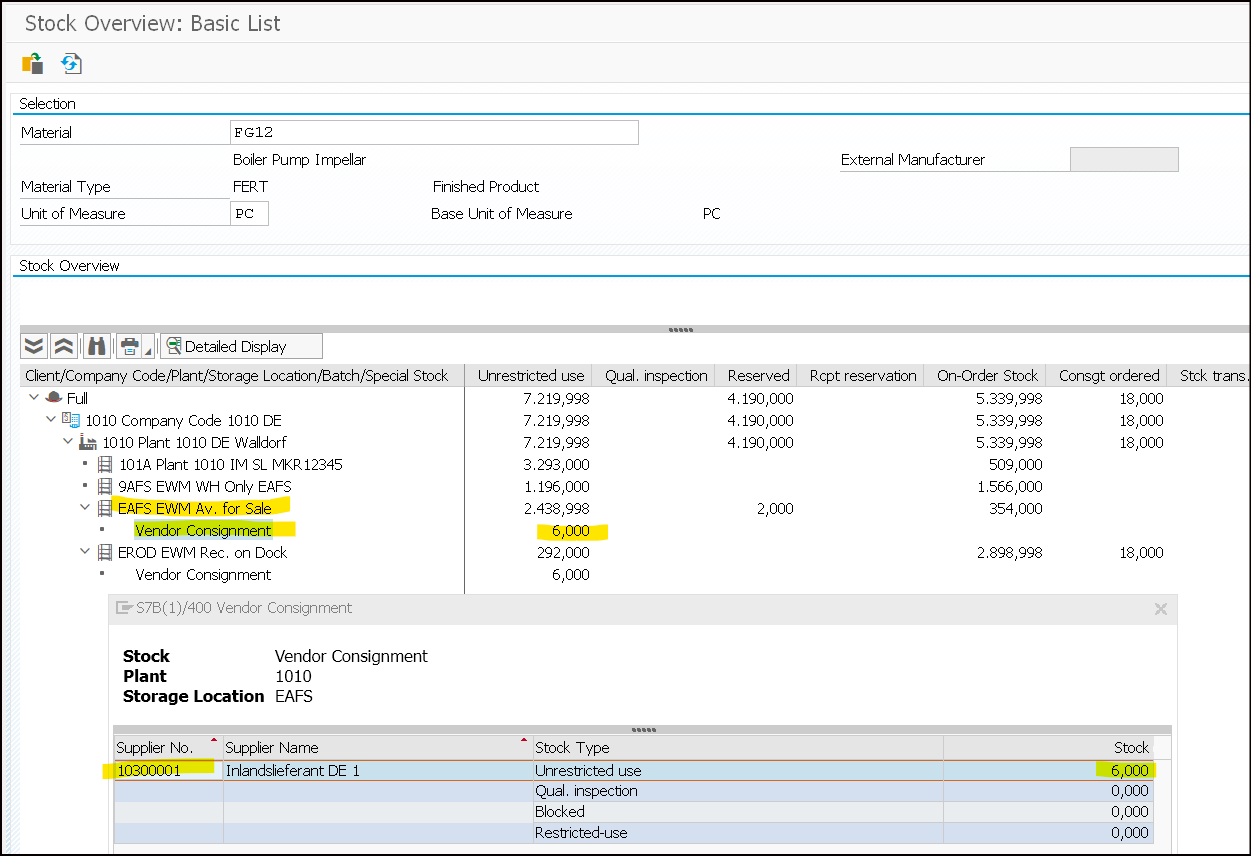

(6) Stock is subsequently putaway to the destination bin and the stock appears as consignment stock in EWM warehouse monitor .

(7) Stock now appears as consignment stock in ERP storage location (Available for sale).

Stock is still in consignment stock (with no liability to pay) as is evident from MB51.

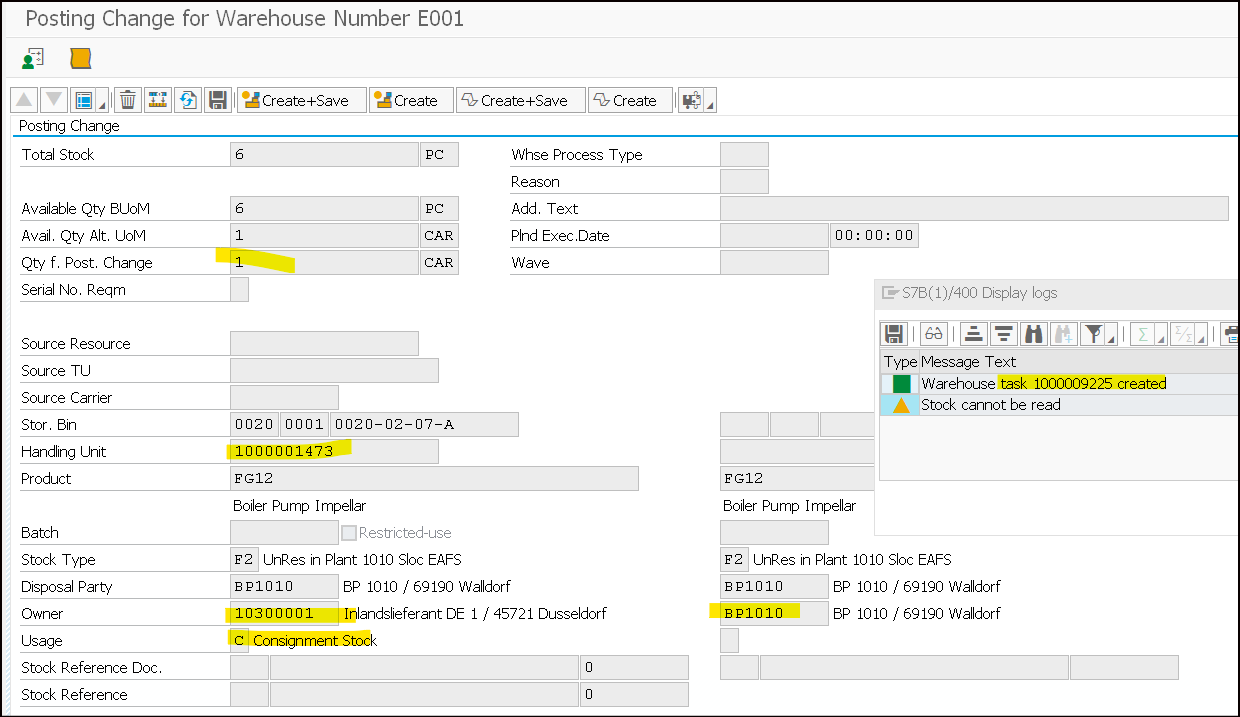

(8) When the material is required, posting change is carried out in EWM for the transfer of ownership from the vendor to the own stock (plant or party entitled to dispose) with reference to the corresponding handling unit.

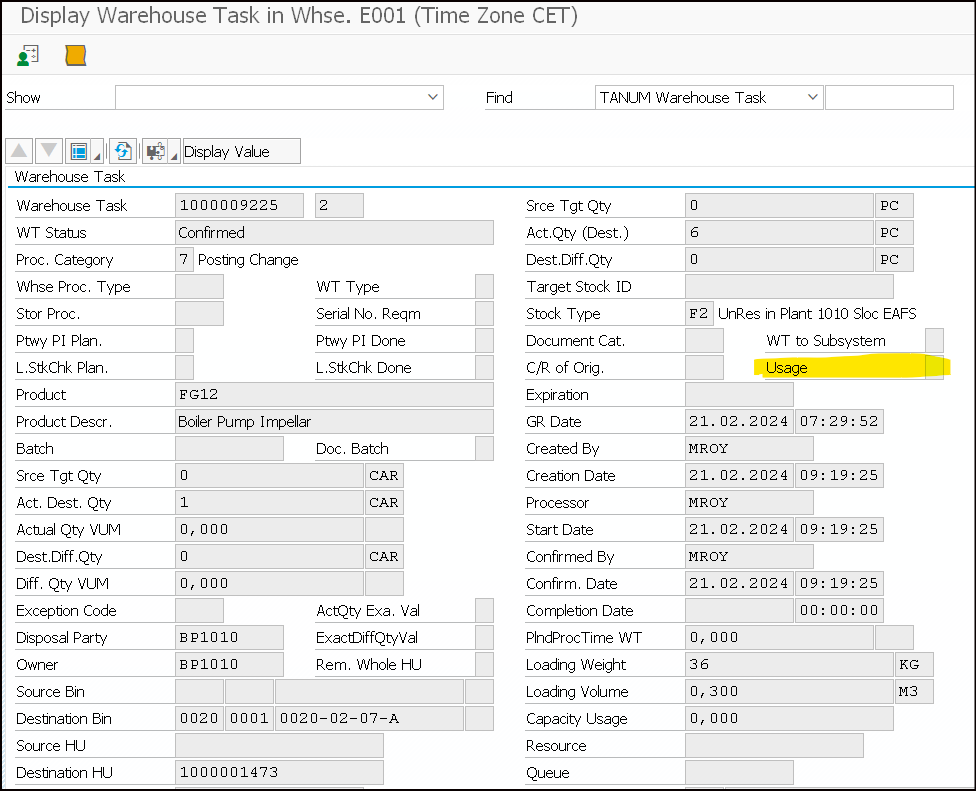

With the creation of warehouse task for the stock to be used for own consumption.

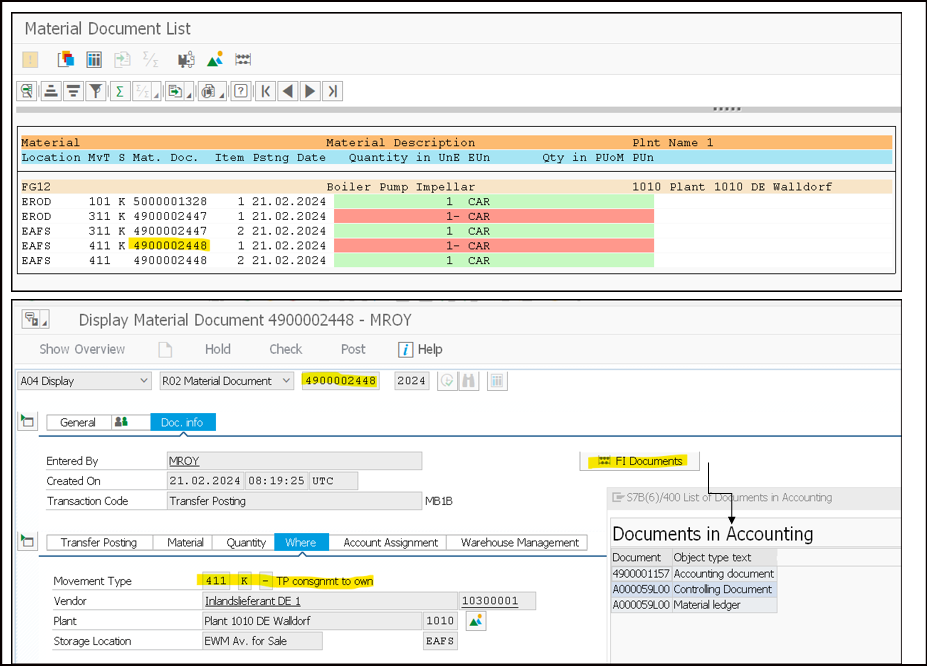

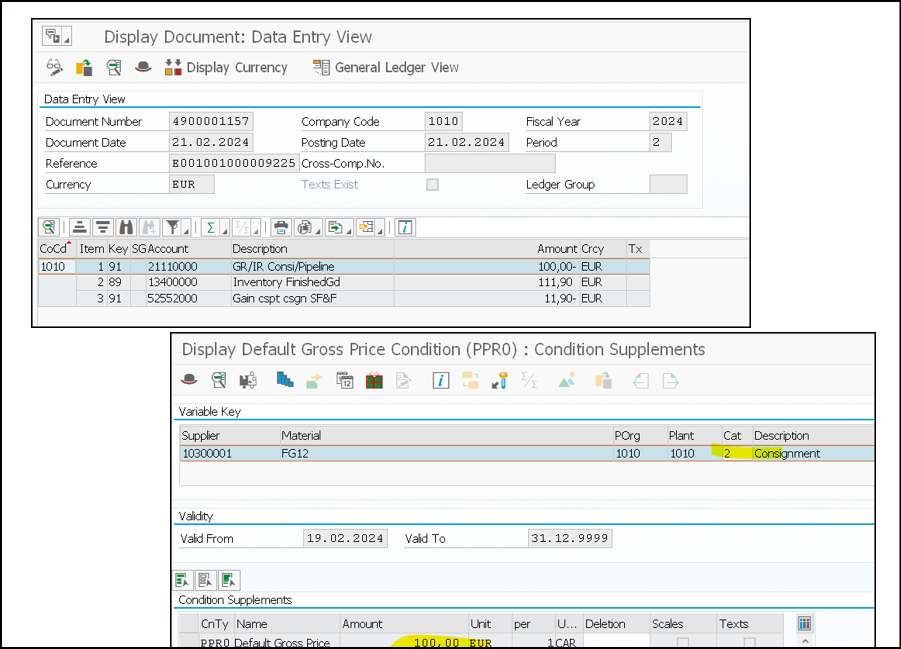

(9) Ownership of stock is then transferred from the vendor to own stock as depicted in the material document created in ERP with movement type 411 K . Material document has now an accounting document to create the liability for the vendor .

Value in the accounting document matches with the purchasing info record for material for consignment.

Vendor consignment is supported in both embedded and decentralized deployments.

This blog is based on my personal insights, observation, and tests. Will appreciate your views / comment and feedback.

Nenhum comentário:

Postar um comentário